Outdoor Kitchen Solutions

Build high-quality, modular and customized outdoor kitchen systems for residential, commercial and mobile spaces.

APPLICATIONS SOLUTIONS

ORISEN's outdoor kitchen system is widely used in high-end residential courtyards, villa terraces, outdoor dining areas of star-rated hotels, open-air kitchens of catering companies, and mobile kitchen scenes such as RVs. Through modular design and flexible customization, it meets the needs of different environments, functions and aesthetics, helping customers create professional, efficient and beautiful outdoor cooking and leisure spaces.

SERVICE SUPPORT

OEM/ODM customized services

· Support brand customization and structural optimization

· Proofing and mass production according to customer drawings

· Provide laser cutting, welding, spraying and other process services

Space planning and customized design

· Provide 3D design and CAD drawing output

· Support multiple layout combinations: L-shaped, U-shaped, island-shaped

· Adapt to different space sizes and usage requirements

Modular product matching

· Free combination of ovens, sinks, worktops, refrigerators, and cabinets

· High-performance stainless steel + weather-resistant countertops, outdoor-specific materials

· Optional gas, electric heating, charcoal and other heating methods

Installation and after-sales support

· Installation videos and instruction manuals support global delivery

· Provide installation guidance services or local cooperation team support

· Provide after-sales guarantee and parts supply services

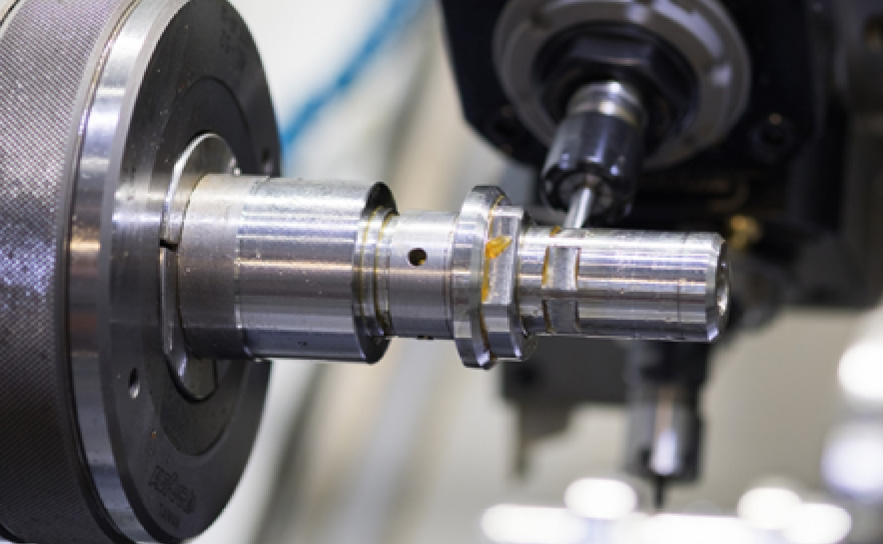

Outdoor Kitchen Manufacturing Support

ORISEN Provides More Finishing Services

◎ Sandblasting

◎ Vapor Polishing

◎ Polish

◎ Painting

◎ Silk Screen and pad printing

◎ Laser Engraving

◎ Anodizing

◎ Electroplating/ plating

◎ Tinted

◎ Powder Coat

◎ Heat treatment

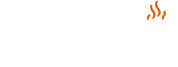

Metal Polishing

Polishing is a processing method that uses polishing tools, abrasive particles or other polishing media to modify the workpiece surface, so as to reduce the workpiece surface roughness and obtain a bright and flat surface.

Metal Painting

Painting include glossy paint ,matte paint , satin paint, rubber painting, UV painting. Painting is a very flexible way to create a different surface appearance.

Metal wire drawing

The metal wire drawing process processes the metal surface through mechanical friction to form uniform and fine lines, which improves the appearance and texture of the metal surface and has a better decorative effect.

Powder Coat

Powder Coat is uses corona discharge phenomenon to make powder coating adsorb on part.

Electroplating/plating

Electroplating is a process that uses electrolysis to attach a layer of metal film to the surface of metal or other material parts, so as to prevent metal oxidation (such as rust), improve wear resistance, conductivity, reflectance, corrosion resistance (copper sulfate, etc.) and enhance beauty.

Laser Engraving

Laser engraving is to use laser technology to engrave characters on objects. The characters engraved by this technology are not scored, and the object surface is still smooth, and the handwriting will not be worn.